CNC LATHE

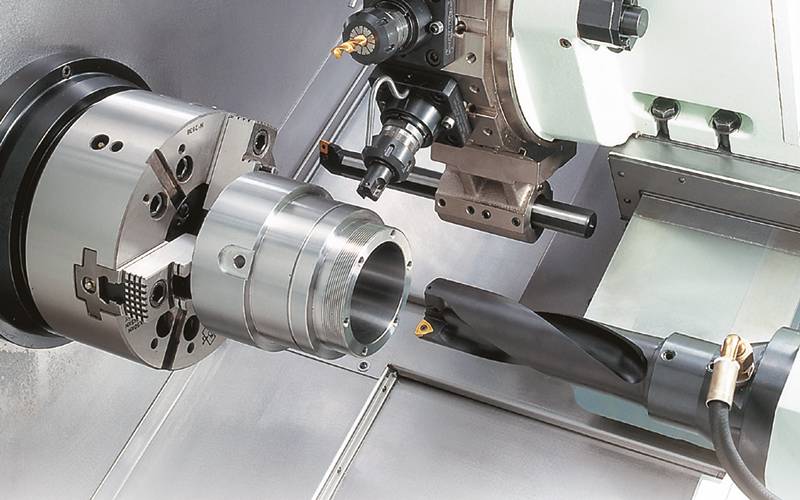

CNC lathe is a machining machining method that works using CNC (Computer Numbered Control) technology. Turning is a process that enables the removal of excess material by turning a workpiece. CNC lathes machine by turning the workpiece and controlling the cutting tools.

The CNC turning process usually consists of these steps:

Design: Designing the workpiece using CAD (Computer Aided Design) software and determining the machining properties.

Programming: Generating CNC codes that determine how the workpiece will be machined. These codes include cutting paths, speeds, cutting tool usage, and other machining parameters.

Preparation: Preparation of a lathe where the workpiece will be mounted, placing the cutting tool and making the necessary adjustments for machining.

Manufacturing: CNC codes are loaded into the machine and the turning of the workpiece begins. By rotating the workpiece, the cutting tool performs operations such as cutting, profiling, drilling, surface treatment on the workpiece.

Control and Monitoring: The CNC machine monitors the machining process in real time and makes adjustments as needed. The quality of the workpiece is checked using measuring devices.

CNC lathe is used for machining many different materials, for example, it is widely used for machining materials such as metal, plastic, wood. This machining method provides high precision, repeatability and processing speed.

CNC lathes can handle a wide variety of turning operations. For example, operations such as external turning, internal turning, drilling, grooving, taper turning can be done. These machines can precisely machine complex geometries and details of the workpiece.

CNC turning has a wide range of uses in the automotive, aerospace, energy, machinery manufacturing and other industries. This method provides significant advantages in terms of productivity, workpiece quality and machining time.