ASSEMBLY

Machine assembly is the process of assembling a machine or machine components through a manufacturing process to create a finished machine. In this process, the finished machine parts are assembled in accordance with the assembly procedures and fixed to each other using the necessary fasteners.

Machine assembly usually includes the following steps:

Preparation of Parts: Cleaning the manufactured machine parts, smoothing their surfaces and performing post-processing controls when necessary. This step ensures that parts are in proper condition prior to assembly.

Preparation of Assembly Procedure: Preparation of a procedure or instruction for the assembly of the machine. This procedure determines which parts are to be assembled in which order, required fasteners and tolerances. The assembly procedure is created on the basis of design documents, drawings or other documentation.

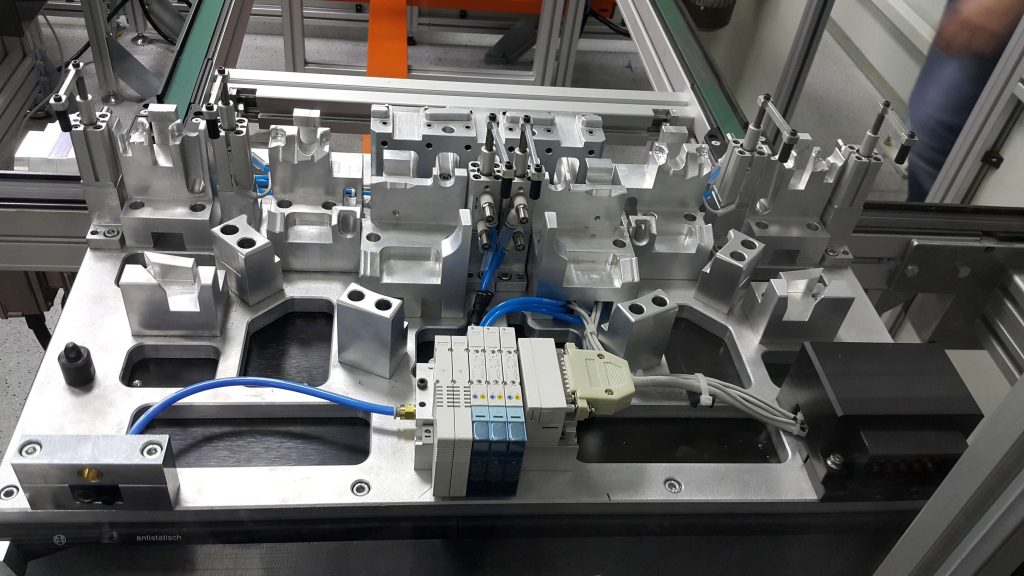

Assembling Parts: Assembling the machine parts in accordance with the assembly procedure. This step ensures that the parts are placed in the correct position and fixed to each other using fasteners. In this process, methods such as screws, bolts, welding, bonding can be used.

Making Electrical and Electronic Connections: Making the connections of the cables and completing the electrical circuits in machines containing electrical or electronic components. At this stage, operations such as wiring, soldering, using connection terminals are carried out.

Final Controls and Tests: Checking the completed machine’s compliance with functional and quality standards. At this stage, all functions of the machine are tested, necessary adjustments are made and quality control procedures are applied.

Machine assembly is an important process used in many different industries. Good machine assembly must be ensured by correct assembly of parts, tight connections and appropriate tolerances.